News

“Will It Be Enough?”: Meatpacking Workers Fear for Safety as Coronavirus Cases Mount

By: Liam Niemeyer | Ohio Valley ReSource

Posted on:

LOUISVILLE, Ky. (OVR) — It’s the uncertainty that gets to Darlene Davis. The uncertainty of when she’ll see her 87-year-old mother in person again. The uncertainty of her co-workers’ health. The uncertainty that comes with the novel coronavirus.

When a co-worker of hers at the JBS Swift meatpacking plant in Louisville died from COVID-19, she said that uncertainty turned into fear for many of the 1,200 employees at the plant. The Louisville Metro Health Department was made aware of the death on April 4.

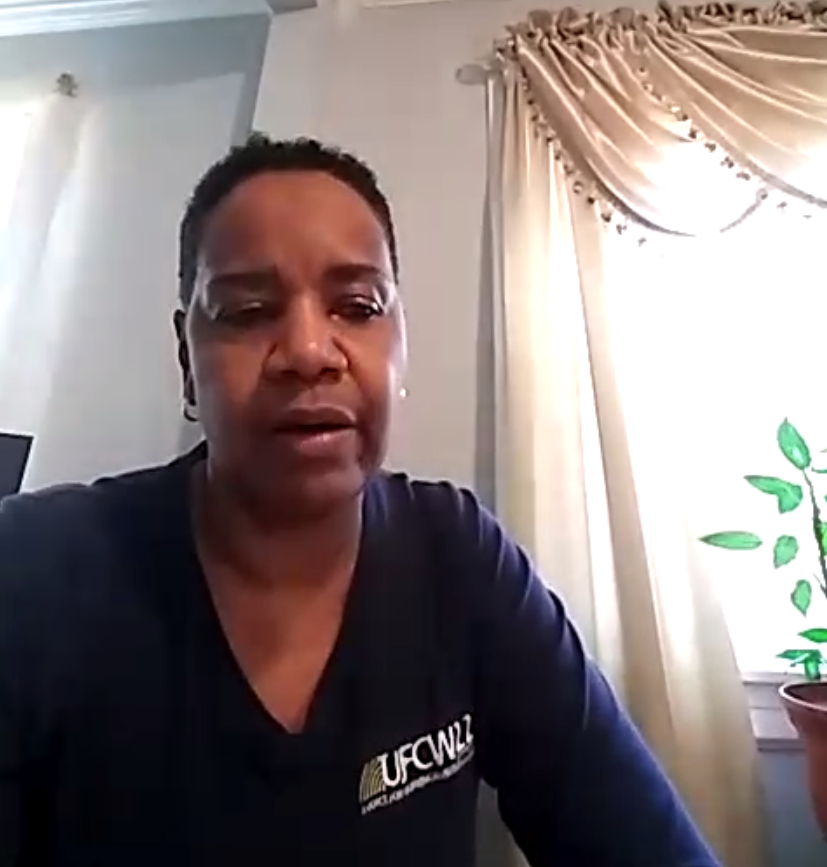

“Everyone was upset because we were close with them, and they was just scared, not knowing the unknown and then having someone that you work so closely with to pass away,” said Davis, the chief union steward at the JBS Swift plant for United Food and Commercial Workers Local 227. “And right away we wasn’t told about his passing or anything like that. But it was very scary.”

That was the first of two coronavirus deaths so far among the at least 481 meatpacking workers sick with the virus in Kentucky. At least 49 deaths have been reported among these workers across the country according to the Food and Environment Reporting Network.

Davis said ever since coronavirus cases began to appear among her co-workers, JBS USA hasn’t done enough to protect them from the virus and hasn’t shared with workers information about positive cases in the plant.

The ReSource spoke with some workers at four poultry and meatpacking plants in the region where coronavirus outbreaks have infected workers. They described the close conditions inside the facilities, their doubts about the safeguards in place, and one worker who has been infected with coronavirus spoke about his fear for his family’s health.

As meatpacking plants are mandated to remain open because of an executive order signed by President Trump, unionized meatpacking workers say they’re potentially being put in harm’s way to keep the nationwide supply of meat flowing because some plants aren’t doing enough to protect them from the pandemic.

Tight Quarters

The Louisville Metro Health Department was notified of a coronavirus death at the JBS facility on April 4 and had received two complaints from workers at the plant following the death, alleging JBS USA wasn’t telling workers about the rise of positive cases in the plant and wasn’t implementing social distancing among workers. A complaint on April 13 alleged that following news that a worker died, other workers who had expressed safety concerns were told they would be fired if they didn’t come into work.

A subsequent inspection by the health department found while some measures were in place to stop coronavirus spread including an outdoor tent for work breaks, there was still not enough social distancing between workers. The plant has had at least 57 workers test positive for the virus as of May 8, along with that one death.

Worker safety advocates have raised past concerns about the tight quarters meatpacking workers operate in, but it’s not just a concern for Davis. It’s a matter of lives at stake.

A spokesperson for JBS said the company is testing worker temperatures, requiring face coverings, and is not punishing workers for absences due to health.

“Reckless Move”

Jason Wilson said meatpacking workers at his Tyson Foods processing plant in Robards, Kentucky, demanded transparency from the start.

“When we had our first case at Tyson in Robards, the company was wanting to keep it a secret, not tell anybody,” said Wilson, the chief union steward for UFCW Local 227 at his west Kentucky plant. “And the union actually told the members, and it [the information] spread like wildfire at that point. And the members got united and more unionized than I’ve ever seen in my life at this plant.”

Wilson said his union members, representing approximately 1,300 employees, have gotten daily updates on coronavirus cases at their plant because of prompt demands. But there are other things that worry Wilson.

The plant in Robards, with at least 95 cases as of Tuesday, was one of 14 meatpacking plants across the country to resume operations this past week following the federal executive order to keep plants operating.

The United Food and Commercial Workers International Union in a release said reopening the plants without providing daily testing and the highest level of protection was a “reckless move” that would put lives at risk.

A Tyson Foods spokesperson previously said the closure of the Robards plant, from April 30 through May 3, allowed for “additional cleaning and sanitation efforts.”

Wilson said plexiglass barriers have been installed surrounding the fronts and sides of each production line worker, and workers are given basic surgical masks. Yet he also said social distancing still isn’t practiced, and his union isn’t yet convinced these barriers are sufficient.

He said about 150 people work tightly together along the labor-intensive ‘de-bone’ production line, which usually has employees remove chicken bones with a knife from breasts, thighs, and legs.

“When we go to the production floor, we’re within 18 inches of the next person.” Wilson said. “At the end of the day, yeah, we social distance in the hallways. But when we go to the production floor, will it be enough?”

These people who make up much of the workforce at these plants are not only falling sick to this virus, but fear they are bringing it back home to their families.

Recovering

Jose Andres works at a west Kentucky poultry processing plant with by far the most coronavirus cases among workers in the state. When the Resource spoke with Andres on April 27, he and his family were just recovering from a weeks-long ordeal with the virus.

“By week one, we came outside and walked in our yard, like one lap and we were exhausted,” Andres said. “This virus does drain you. But thankfully, we were not as critical as most people. We didn’t have to be hospitalized.”

He said his wife, who has an autoimmune disease, was hit harder by the virus. Andres, originally from Guatemala, has grown up in Ohio County, Kentucky, through the Development, Relief, and Education for Alien Minors Act, or DREAM.

His job as a production supervisor at the Perdue Farms poultry processing plant in Ohio County provides his family a stable living, while his wife stays home with their eight-month-old daughter. Andres’ positive case may have been one of the first coronavirus cases at the plant.

He said his fever, edging above 100 degrees, started on Easter Sunday, April 12. The fever wouldn’t break after taking some Tylenol, still persisting by the time he was scheduled to go back to work on Tuesday. He said he went straight to the plant’s Wellness Center, where he was prescribed antibiotics. That didn’t work either.

“And that’s when they told me to go get tested for the virus,” Andres said. “And by that time I had lost my [sense of] taste, my smell, and just body aches … they tested me for strep [throat], flu and of course the virus. And those first two tests came back negative, and that kind of just made me worried that I had the virus.”

Andres said he received a positive test result on April 18. Green River District Health Department officials said they were made aware of the first case at the Perdue Farms plant on April 13.

“By that time, my wife was showing the same symptoms that I had. And we have an eight-month -old baby. So that’s just what came rushing into my head was my daughter. You forget about yourself for a moment and then I was worried about her. And my wife has two boys,” Andres said.

At the time of the interview, Andres said he believed leadership at the Perdue Farms plant was doing the best job they could to protect workers given the circumstances of the virus, including checking worker temperatures and providing masks. A Perdue Farms spokesperson said those measures, along with barriers installed in workplaces and sanitizing the plant every 24 hours, are efforts to keep the 1,300 plant employees safe.

But since Andres’ case, the plant has seen hundreds of cases amongst its employees — 282 as of Tuesday, according to state health officials — and one employee has died. The Kentucky Department for Public Health had all employees at the plant tested for the coronavirus last week, an effort that identified almost 100 additional cases.

State health officials are working with Perdue Farms to update the company’s internal infection control plan with state coronavirus guidance, including recommended social distancing and changing how employees carpool to work.

Yet it remains unclear what can be done by local and state health officials at these plants if coronavirus outbreaks linger or resurface.

Following Trump’s executive order to keep meatpacking plants operating, U.S. Department of Labor guidance said local and state authorities may not be able to force meatpacking plants to close.

In Kentucky, workplace safety regulations are managed by a state agency, the Kentucky Occupational Safety and Health Program (OSH). However, the agency indicates it does not have authority to regulate these facilities.

“Kentucky OSH is seeking a collaborative relationship with the U.S. Department of Agriculture in ensuring the health and safety of meat and poultry processing workers during the pandemic, while respecting the authority of federal officials under the President’s DPA order and U.S. Department of Labor guidance,” said Majorie Arnold, Chief of Staff for the Kentucky Labor Cabinet.

Small Sacrifices

For some union meatpacking workers in the region, relationships with plant leadership have been less strained. Belinda Arms is the chief union steward for UFCW Local 227 and a chemical operator at the Tyson Foods processing plant in Corydon, Indiana.

“I have to say that our plant has really stepped up to the plate for once they have done a great job, they’ve been totally transparent. Anytime that we have a new case, the HR manager, she will call me,” Arms said.

With at least nine coronavirus cases at the plant, Arms said the good working relationship she had with plant management before the pandemic has carried over in the past few months.

So far, OSHA has only issued optional guidance for meatpacking plants.

“I think that the difference in experience, not just from different companies, but also within the same company, is really a perfect example why we need state leaders to step up and make these guidelines, the CDC guidelines mandatory for everybody, and enforceable so that every plant can experience the same level of protection,” Blair said.

Even with fears of the coronavirus, many of these workers go into these plants because they rely on the paycheck it provides. For Darlene Davis, his husband is out of work with a broken leg, unable to contribute an income.

With Mother’s Day this past weekend, Davis didn’t consider visiting her elderly mother who is living with another family because of coronavirus fears.

“Because of her age and this virus is going on, me going into the plant every day, I wouldn’t want to take that back to her,” Davis said. “I had one friend tell me that because of this going on, when he comes home, his wife is in one area of the house and he stays in another area so that they won’t spread the virus just in case.”

During normal times, Davis would gather with her mother and other family to have dinner and sit on the front porch as the weather warmed up. But with the uncertainty of the pandemic, Davis is having to make that sacrifice.